The next generation of science-based solutions

Woods Hole Group solves environmental engineering problems worldwide with a focus on serving clients along the coast, in the ocean, and in wetland and terrestrial environments.

Relying on service, excellence and leadership, Woods Hole Group employs experienced engineers, scientists, and technicians.

Learn more about us

3,000+

projects in more than 35 years of consistent business operations

4,000+

animals currently tracked and 4,000+ fishing boats

100

employees in 4 USA offices

Our Solutions

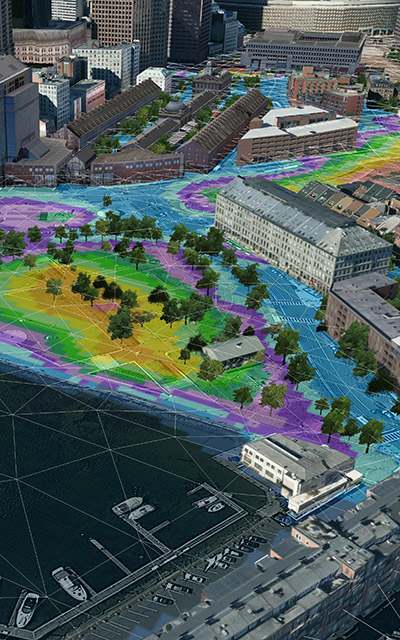

Environment

& Climate

Innovation at the heart of Woods Hole Group

Innovation at Woods Hole Group is proactive. We are successfully turning ideas into products and solutions that help clients move forward in improved ways.

Kirk Bosma, Woods Hole Group Vice President, Innovation

Testimonies

We are very pleased to have developed a great working relationship with Woods Hole Group over these past two contracts. It is refreshing to find a consultant that is so easy to work with, and can effectively manage our interests with the best interest of the science.

From a representative of a leading offshore wind development company in USA

I have to congratulate you and your team for a truly outstanding document. The comprehensiveness of what you undertook and the implications for policy changes in so many places boggled my mind as I thought about the complexity of the work you had to undertake. This was a remarkable effort. On behalf of myself and other Palm Beach residents, I’d like to share my heartfelt thanks. In Palm Beach we have a jewel that is similar to Nantucket, Venice, Capri, etc. I hope we are able to preserve it for future generations.

From a citizen of prominent Town of Palm Beach, FL

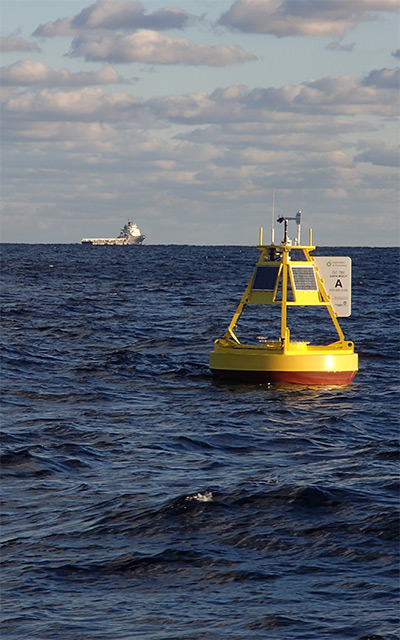

This company adjusted to the pandemic with operational excellence. No stations were left unattended, even when travel restrictions were at their worst. Exceptional work.

From a NOAA representative on CPARS

Latest News

DeepCLiDAR – Stage 2 Carbon Trust Certified Floating LiDAR

DeepCLiDAR, designed and built by CLS (a subsidiary of the French Space Agency), in partnership with the University of Maine, has obtained Stage 2 Carbon Trust Certification, making CLS a unique...

Woods Hole Group – Satellite Telemetry

At Woods Hole Group, Inc. we are the unique ARGOS satellite system operator in North America. ARGOS is a unique worldwide satellite location and data collection system dedicated to studying and...

Happy Holidays & Happy New Year!

We all know our planet is suffering, so let's get straight to the point. At Woods Hole Group, we have: data, continued services, expertise, value added proposals, people who care, to make our planet...

Working at

Woods Hole Group

We are growing

Our work is a collection of scientific disciplines, not a single science.

Our team of experts applies latest technologies to solve the real-world problems our clients are facing. We want to change the world and make our planet a sustainable Earth.

If you want to give meaning to your daily life, make the Earth your playground and embark on an exciting professional adventure, then you are just a few clicks away from our current opportunities!

“We cannot solve our problems with the same thinking we used when we created them.”

– Albert Einstein